Pillar Drilling Machines, Bench Grinding Machines, Polishers

Pillar drilling machines, also known as pillar drills or column drills, are stationary machine tools used for drilling holes in various materials. They consist of a vertical column that supports a drilling head with a motor, spindle, and a worktable. The drill bit is attached to the spindle, and the machine is designed to provide precision and stability during drilling operations.

Pillar drilling machines are used in various industries for:

- Metalworking: Drilling holes in metal sheets or components.

- Woodworking: Creating holes in wooden materials.

- Construction: Drilling holes in construction materials.

- Manufacturing: Precision drilling in the production of parts and components.

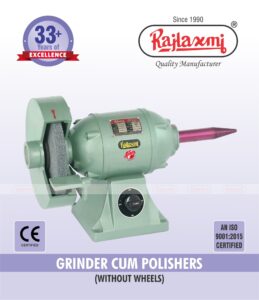

Bench grinding machines are tools used for shaping and sharpening metal, wood, or other materials. They typically consist of a bench-mounted grinder with grinding wheels, and the user operates the machine from a seated position. These machines are versatile and can be used for various grinding tasks.

Bench grinding machines are used for:

- Sharpening tools: Such as chisels, drill bits, and knives.

- Shaping metal: Grinding and smoothing metal surfaces.

- Removing burrs: Eliminating rough edges from metal or other materials.

- General-purpose grinding tasks.

Polishers are power tools used for polishing and buffing surfaces to achieve a smooth and glossy finish. They are commonly used in automotive detailing, woodworking, and metalworking to enhance the appearance of surfaces.

Polishers are used for:

- Automotive Detailing: Polishing car surfaces to remove scratches and enhance shine.

- Woodworking: Polishing wooden surfaces to achieve a smooth finish.

- Metal Polishing: Bringing a high shine to metal surfaces.

- Marble and Stone Polishing: Enhancing the appearance of stone surfaces.

These machines play essential roles in workshops, manufacturing facilities, and industries where precision drilling, grinding, and polishing are required.

PRODUCTS